Creep and Stress Rupture Properties :: Total Materia Article.

Creep strength and rupture strength are commonly used when designing or using pipe or tubing. Rupture strength is defined as the stress at specified environmental conditions (temperature, humidity and sometimes chemical environment) to produce rupture in a fixed amount of time usually given in hours.

The creep rupture strength of the cast alloy was similar to that of the wrought alloy, because such defects and segregations influencing the TS grew out of, or partially dissolved, during creep; thus, their effect was gradually eliminated.

Rupture strength - definition of rupture strength by The Creep and Stress Rupture Properties :: Total Materia Article Improving the Notch-Rupture Strength of Low-Expansion Tensile Rupture of a Member - B G Structural Engineering Creep rupture strength Article about creep rupture Creep and Stress Rupture - North Carolina State University.

The creep rupture test (stress rupture test) is used to measure the high-temperature strength of materials that are subjected to constant stress at elevated temperatures over a longer period of time. Note that the phenomenon of creep also occurs at relatively low temperatures.

Abstract: Creep is defined as the time-dependent strain that occurs under load at elevated temperature and operates in most applications of heat-resistant high-alloy castings at normal service temperatures.

Creep testing (creep-rupture, stress-rupture, stress-relaxation) is conducted to determine the deformation (creep) of a material when subjected to a prolonged load at a constant temperature. A creep test has the objective of measuring creep and creep rates occurring at stresses usually well below those which would result in fracture.

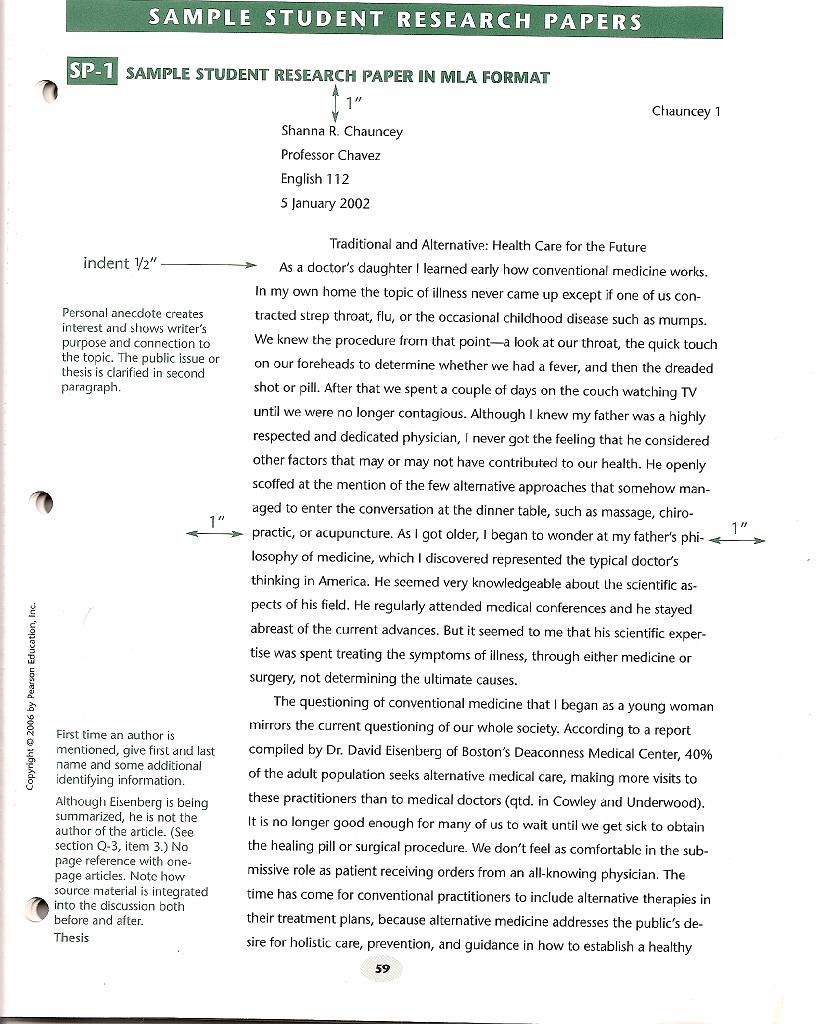

Creep and Stress Rupture Properties. Creep Properties Creep is a time-dependent deformation of a material while under an applied load that is below its yield strength. It is most often occurs at elevated temperature, but some materials creep at room temperature. Creep terminates in rupture if steps are not taken to bring to a halt.

Related to rupture strength: creep rupture strength the measure of the force necessary to break a given substance across, as a beam, expressed by eighteen times the load which is required to break a bar of one inch square, supported flatwise at two points one foot apart, and loaded in the middle between the points of support.

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. It can occur as a result of long-term exposure to high levels of stress that are still below the yield strength of the material.

The creep threshold values of the coal samples with different moisture contents is given in Table 2, while the threshold coefficient is the ratio of the creep threshold stress value to the creep strength. The creep threshold values the minimum stress level of creep deformation.

Flexural strength also known as modulus of rupture, bend strength, or fracture strength, is a material property, defined as the stress in a material just before it yields in a flexure test. The flexural strength represents the highest stress experienced Within the material at its moment of rupture.

The alloy in the form of forged bar, plate, or extrusions was to be subjected to a number of potentially long term damaging mechanisms (1) including fatigue, creep, creep-fatigue, and loss of strength due to overaging. It was expected that.

Creep is the time-dependent deformation of a material while under an applied load below its yield strength. Creep testing is most common at elevated temperature, but some materials will exhibit creep at room temperature. Unless stopped, creep testing terminates in rupture.